Design

Design

Since 1964, when Advance Mfg. was granted the first patent for our line of wrenches, we have strived to keep pace with technology. This drive has taken us from pencil and board, to the latest in CAD software running on up to date computer workstations.

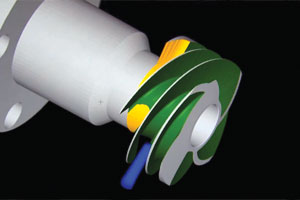

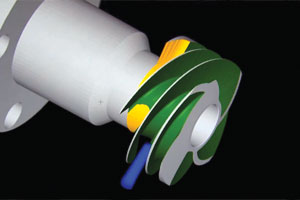

Staying current with today’s technology allows us to model our wrench designs in 3-dimensional form. Use of these 3-dimensional models gives us the ability to check for form, fit, function, and to present our wrench designs to the customer in a clear, easily visualized format.

All accomplished without cutting any metal, this saves time and money, two important commodities in today’s market.

Our in-house engineers design and develop torque wrenches for use on applications that require fastening or unfastening of threaded elements in aircraft engines, helicopters, submarines, public utilities and construction industries.

Advance Mfg. designs our products to produce an accurate torque, ranging from 14,400 to 1,000,000 in-lbs. Our designs have gained worldwide acceptance.

Safe and simple to use, our wrenches completely eliminate the strong arm, backbreaking work currently required to operate mechanical type torque multipliers: they can be used to full capacity by using only fingertip control.

If you have a blind torquing application requiring precise, documented, torque control, contact our engineering department to discuss your requirements.