Satellite Inspection Station (SIS)

Satellite Inspection Station (SIS)

Advance Mfg. Co., Inc. Quality Policy:

Our Goal is customer Satisfaction and Excellence in All We Do. We Pledge our Total Commitment to Quality. Anything Less is Unacceptable.

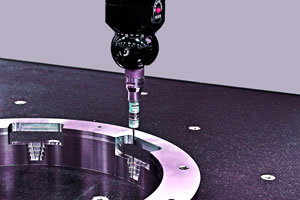

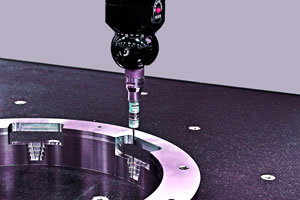

One of the hallmarks of working with Advance is our environmentally, electronically controlled Inspection Department where CMM machines are programmed to measure and inspect the closest-tolerance parts throughout the entire manufacturing process.

For added efficiency, we have several Satellite Inspection Stations throughout the plant that allow for in-process inspection.

Our Quality Engineers and our Compliance Manager also ensure that specifications and results are on target. We create and verify inspection reports, quality documents, and certifications to customer requests. In fact, our entire inspection practices often go above and beyond.